In the past recent decades quality in production has been, thankfully, one of the most basic significant issues in developed countries industry. Gradually this factor was entered in developing countries.

Firstly, owing to the fact that uPVC doors and windows industry is a fledgling industry in our country Iran, there has been, unfortunately, a deprivation of establishing a centralized organization in order to define compulsory standards and obligations in the context of quality control over the products mentioned before. Furtherly with the existence of a myriad of unstandardised workshops which has become a growing phenomenon, operationally, quality control in uPVC doors and windows assembly industries has been pushed to margins or in the most optimistic case, completely is being carried on in a non-standard manner.

Perhaps merely, in a small number of reputable accredited active manufacturing companies, great strides have been taken to establish proprietary system of uPVC products quality control.

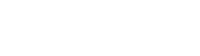

Pursuant to the subjects mentioned above and to embark on a career in right direction towards establishment of a quality control system in the field of manufacturing uPVC products, HooramCo. has constituted the quality control department in the factory.

The first step was to identify the sources and standards used to determine the road map needed then proper action to form a special committee consisting of technical experts & engineering and QC was taken, after conducting the required research and communication with experts in the field of production systems, road map of the company’s quality management system was deployed.

After compiling an overall framework to establish quality control system, the executive stepwise phase started to plan the establishment of a quality control system.

Generally, the system of quality control and after-sales services of HooramCo. Could be counted as a network of procedures and technical information to produce a high quality product and could be summarized as below:

- Control plan

- Inspection of incoming raw materials

- Authentication and set up

- Process control and field product

- Quality warning and declaration form fraction

- Corrective and preventive action form